|

EndSealer 500 - Custom Series

USER’S MANUAL

PLEASE READ ENTIRE MANUAL BEFORE OPERATING THIS EQUIPMENT

Introduced February 2012

All Products Designed & Manufactured by Novaseal Corporation

in the United States since 1994. All Rights Reserved.

|

INDEX:

|

|

|

IMPORTANT SAFEGUARDS

- Read all instructions prior to operating.

- Warning: Electric shock could occur if used incorrectly or on wet surfaces.

- Do not touch hot surfaces.

- Keep hands, feet, loose clothing away from hot sealing die.

- Do not immerse any part of this product in water or other liquid.

- Do not use this product on wet or damp materials.

- Never use EndSealer in presence of flammable or combustible liquid or fumes.

- Do not cool the sealing die with liquid.

- Always operate product in a well-ventilated area or operate outdoors.

- Unplug product when not in use. Allow to cool completely before storing. Store in clean, dry area.

- Do not operate this product if cord or plug has been damaged in any way. If cord or plug is damaged, return this product to manufacturer for repair or adjustment.

- Never leave plugged-in product unintended.

- Use EndSealer only for its intended use as described in this User’s Manual.

- Appropriate, non-flammable work gloves are recommended to be worn when operating EndSealer.

- Manufacturer recommends wearing respirator when working with materials that generate toxic or hazardous fumes.

- Do not drop product.

- If power source or generator fails while the EndSealer is in use, simply turn off EndSealer, recharge power source or generator, and re-start EndSealer per instructions.

- Product must only be used with 110/120 VAC 50/60 Hz power source.

- WARNING: Sealing Die cooling time varies with ambient air temperature, operating temperature, existence of wind, etc. and therefore may take longer than expected to properly cool before touching the Sealing Die.

- All repairs must be made by qualified personnel at Novaseal. If repairs are necessary, package EndSealer securely and ship via prepaid UPS or FedEx service to attention of Customer Service, Novaseal Corporation, 6601 Lyons Road, Suite E-4, Coconut Creek, FL 33073 USA.

SAVE THESE INSTRUCTIONS

NAMING CONVENTION

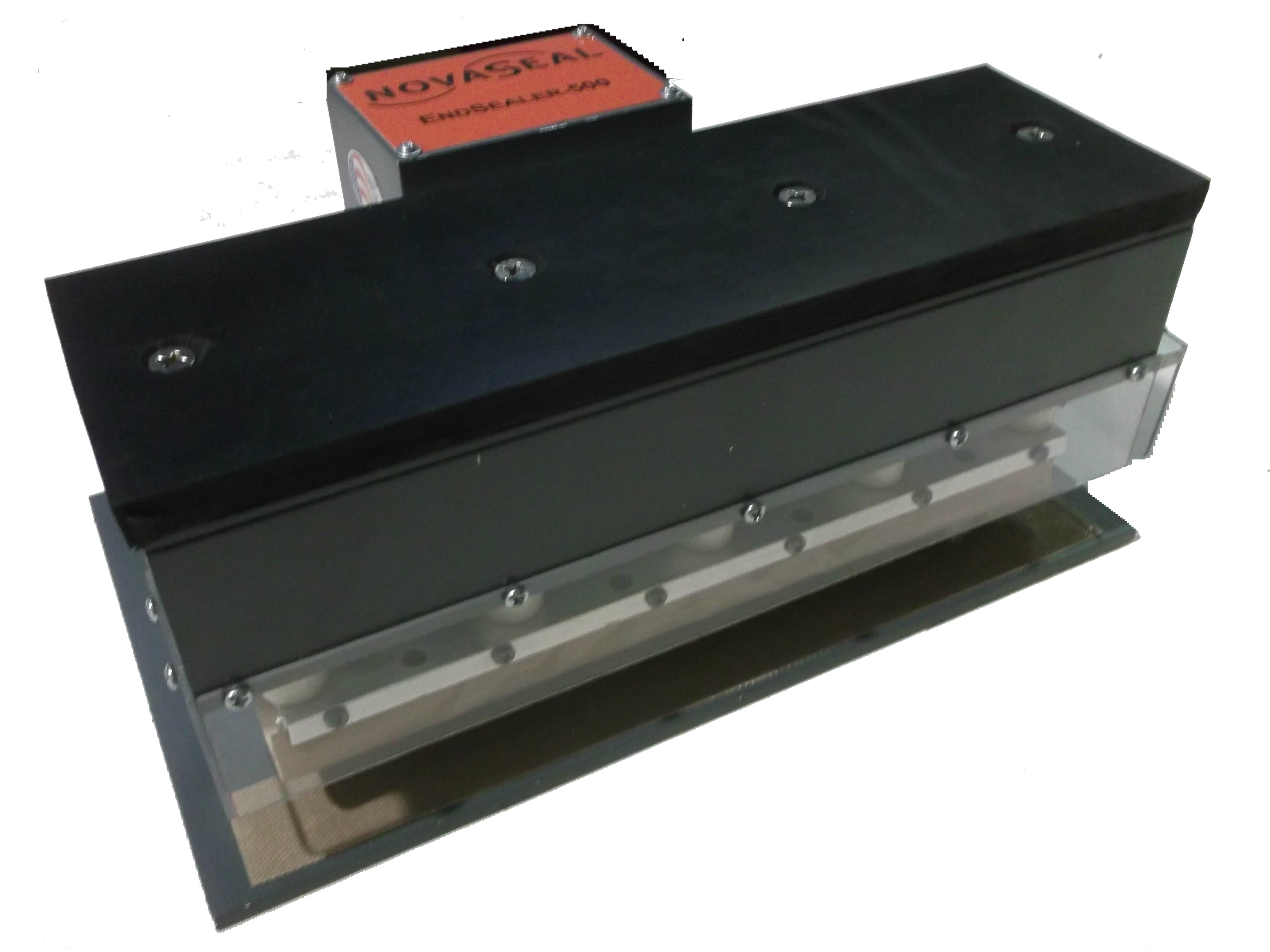

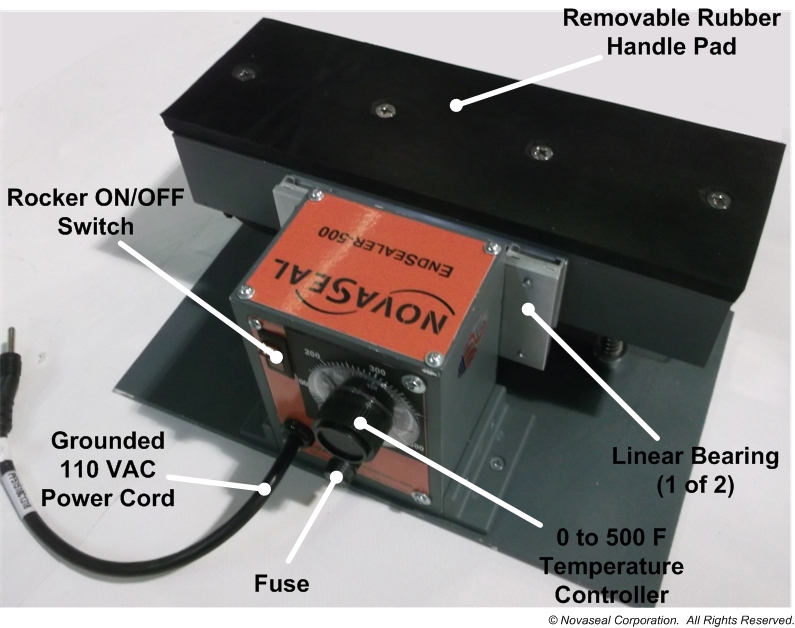

The following images define our standard naming convention as it relates to the EndSealer. Reference to these names will be referred to throughout this document.

USE PREPARATION

ENDSEALER MUST ONLY BE POWERED BY A 110/120 VAC 50/60 HZ POWER SOURCE. TO AVOID ELECTRICAL CIRCUIT OVERLOAD OR POSSIBLE SHOCK, DO NOT USE WITH OTHER THAN 110/120 VAC 50/60 HZ POWER SOURCE.

- Before plugging in the EndSealer, make sure that the moveable press section can move freely up and down with slight pressure. Make sure the springs are maintaining an UP position.

- Additionally, make sure that the TCF Pad and TCF Material encompassing the Heat Die are in good condition.

- And make sure all screws are tight.

INSTRUCTIONS

As common with virtually all Novaseal machines, controls are simple and machines are easy to use. EndSealer is no different. The EndSealer Custom series is used with any variety of sealing dies as compared to standard die size of 1/4in x 2in. Simply, locate the material you desire to seal under the Heat Die and press down the spring-activated hand press, hold in place for desired amount of time, then release. On most materials that is all you need to do. On some materials, cooling pressure is needed to permanently secure the heat sealed materials. If cooling pressure is needed, either use our optional Heat Seal Block, or any other heat sink material. Determining the amount of time to heat seal a material is best accomplished using trial and error methods. The two basic variables in producing optimal seals are seal temperature and seal time. When using our default settings for seal temperature, sealing time becomes the only real variable.

1. Use the Rocker ON/OFF Switch to turn on the EndSealer. EndSealer Controls are located at the rear of the EndSealer. When the EndSealer is ON, the Rocker Switch Lamp will illuminate. 1. Use the Rocker ON/OFF Switch to turn on the EndSealer. EndSealer Controls are located at the rear of the EndSealer. When the EndSealer is ON, the Rocker Switch Lamp will illuminate.

2. Next set the Sealing Temperature. Look for the Temperature Dial. Rotate to desired value. Set temperature ranges from room temp to 500-deg F. Allow about 5 minutes for heat up and could be longer with larger dies. There is no indicator lamp that will tell you when the set temperature is met. Rotating the Temperature Dial clockwise will increase Heat Die temperature. Temperature gradients are marked as degrees F.

3. Sealing Die heat is always on. When making a seal, press down the via the Rubber Handle Pad. Everything other than Handle pad may be hot to the touch. For best seals, apply even pressure along the length of the sealing die. When the seal is complete, stop pressing down, and the Rubber Handle Pad with handle structure will return to UP position. When the handle structure is in the UP position and the Rocker Switch is on, the Sealing Die will remain HOT. The only way to turn off the heat is by toggling the Rocker Switch to OFF position.

TROUBLE SHOOTING

|

Problem

|

Remedy(ies)

|

|

Power Light off and Heat Die Hot

|

- If the Rocker On/Off Switch red indicating lamp is not on and the Rocker On/Off Switch is in the up position and the Heat Die is hot, then the lamp in the Rocker On/Off Switch is no longer operational. Return EndSealer to Novaseal for Rocker On/Off Switch replacement.

|

|

Power Light illuminates and No Heat.

|

- Check Temperature Setting. Set temperature may be too low.

- Carefully determine if the Heat Die is cold. If the Heat Die is cold to the touch, then the Heating Element may need to be replaced. Contact Novaseal for Heating Element replacement instructions or return EndSealer to Novaseal for Heating Element replacement service.

|

|

Power Light doesn’t illuminate and No Heat.

|

- Check Rocker On/Off Switch. Try turning the machine on again.

- Check Power and Power Cord integrity.

- Check Fuse.

|

|

Material takes too long to heat seal.

|

- Check Temperature Setting. Some materials require more heat or time to seal.

|

|

Heat Seal seems to discolor sealed material.

|

- Check Temperature Setting. Try lowering temperature.

- Check Seal Time. More time exposes material to more heat. Too much heat will burn or discolor the sealed material.

- Check TCF material around the Heat Die. If the Teflon layer of the TCF material is worn, the Fibreglas layer will slightly discolor the sealed material. Replace the TCF material on the Heat Die. Also check the integrity of the TCF Pad. If similar condition replace TCF Pad.

|

|

Heat Sealed Material “sticks” to Heat Die.

|

- Check Temperature Setting. Too hot may cause sticking.

- Check Seal Time. Too long an exposure to the heat may cause sticking.

- As the TCF material wears, the Teflon layer is no longer exists. The Teflon layer allows for easy release. Without the Teflon layer, the TCF material may appear or will seal to your heat sealed material. Replace the TCF material affixed to the Heat Die. Also check integrity of TCF Pad. Replace TCF Pad as needed.

|

|

My Problem is not Listed in this Trouble Shooting section.

|

- Contact Novaseal. Report the problem and we’ll update the Troubleshooting Section to include relevant problems.

|

|